| |

|

|

| |

Cotton Roll |

| |

|

|

| |

| |

| |

Superfine Bowl Filling |

(a) Cotton Bowl for Textile Calenders

CX - Combination comprise of conditioned, carded carefully laid cop bottom

superfine cotton material.

(b) Cotton-Comber bowl for super calender (Paper Industries)

CXI - Combination comprise of conditioned, carded and carefully lad blend of superfine cotton

and cop bottom material homogeneously mixed.

Cotton material is well built in lap/cake form under hydraulic pressure for filling.

Seasoning of cotton cake under controlled temperature and humidity is a unique feature.

|

|

| |

Selection of Raw Material |

CX combination is most suitable for processing textile fabric in universal and friction calender & Tinning Finishing.

CXI combination is mainly used for processing coated paper in super calenders for its silky and glossy finish. |

| |

|

| |

| |

Construction |

The heart of a cotton bowl is steel core made of high quality medium carbon steel which can withstand maximum resistance to failure by fatigue. Steel shafts are thoroughly inspected for hidden cracks, weak spots etc., and are made true prior to installation in hydraulic press.

New end plates are manufactured out of forged steel thoroughly examined by ultrasonic crack detector for any defect.

The plates are turned on most modern machines under strict supervision |

| |

|

| |

| |

Cotton To Calender Bowl |

Bowls are built around a strong steel core held vertically into the specially designed hydraulic press. Cotton laps/cakes punched as its centre are lowered from top which are axially compressed hydraulically.Periodic filling and compression ensures the cotton mass to settle without airpockets. The bowl is finally locked at the top with the help of already turned and prepared steel end plates. |

| |

|

| |

| |

Smooth and Silky Surface Finishing |

Finishing of refilled bowl is an important step in the bowl manufacture. Bowls are turned initially with carbide tip tool and later with diamond tool.The silky & glossy finish is produced by applying fine count emery paper. |

| |

|

| |

| |

Some Hard Fact of Cotton Bowl |

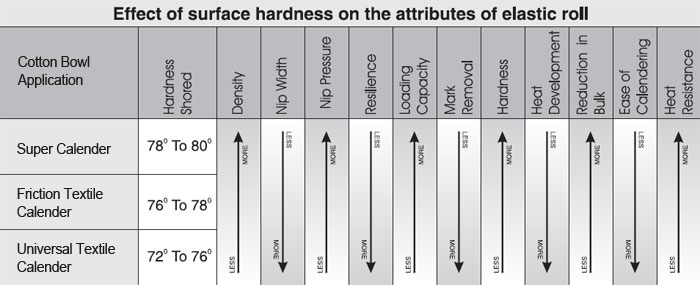

Raw cotton C-XI filled bowls are sometimes used in mills with slow running calenders. These are much more elastic than paper bowls.Due to its resistance and excellent quality of glass 0 finish this is widely used in production of coated printing paper.Usually made at 78-80 shore D hardness. Its resiliance allows crease marks to be easily wiped out provided they are not too deep.These are limitations on speed and pressure maximum of 400 m/min. and 200 kg./cm. Higher speed & pressure will result in burning and busting. |

| |

|

| |

| |